PLC Engine Collect connects programable controllers,

supervisory control systems and devices among themselves and with the

automation world. It connects controllers and databases, too. Likewise

it works as OPC server and OPC client to SCADA Systems.

With BACnet and KNX/EIB it openes controllers and databases to the building automation.

Take Your tablet or smartphone for a fast view oy Your plant.

Over Ethernet it offers access to the controllers from the companies

Siemens, Rockwell Automation, Wago, Modicon, Schneider Electric and

others.

OPC UA and MQTT opens the Industrie 4.0 and IoT world.

You implement Euromap, UMATI, PackML and other standards quickly and easily.

PLC Engine Collect is simply to configure. Wizards are offering frequently needed standard functions.

The PLC Engine allows data processing in production lines.

It connects controllers, devices, SCADA systems and databases from various

manufacturers. It processes the data and dispatches them between the

connected devices and other systems. It collects data, manages them and

creates overviews for OEE applications.

Additional all the data can be handled over OPC. This are processed data and

all data from the connected controllers, devices, OPC systems and databases.

PLC Engine is the perfect component for using it for communications in

Industrie 4.0.

The configuration works in graphical style or with simple lists.

Lot of Wizards simplify this.

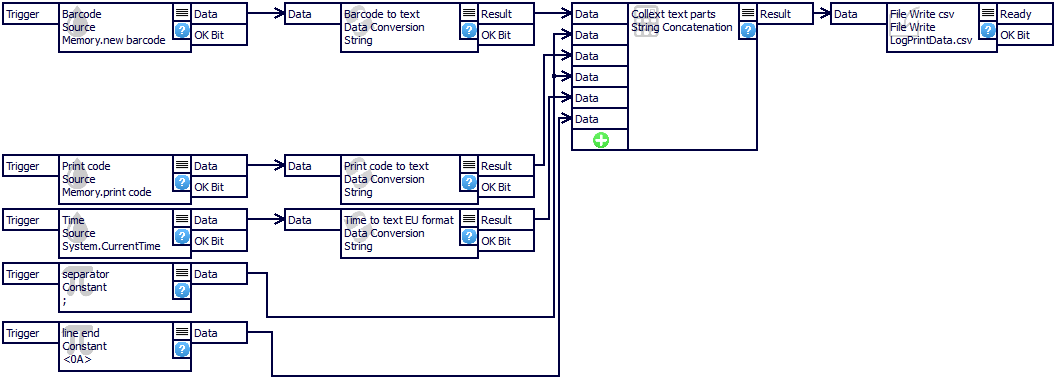

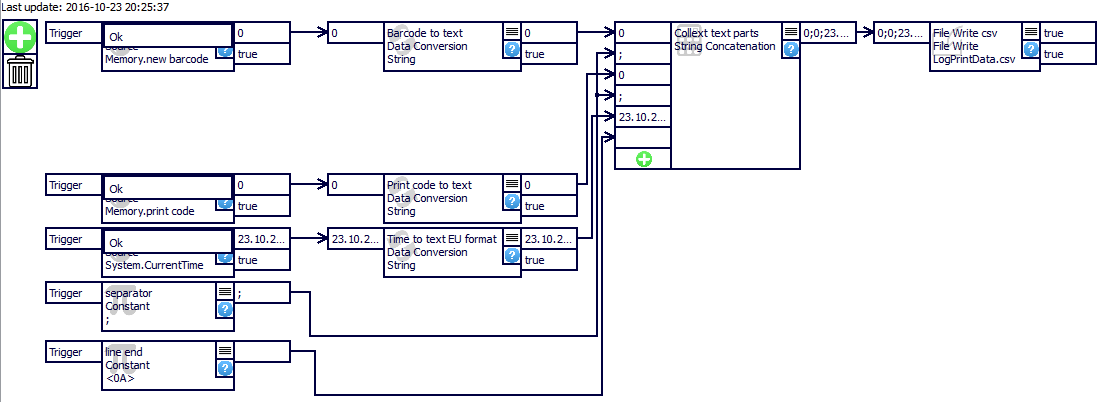

The example logs from barcode reader, adds a timestamp and writes both into a .csv file.

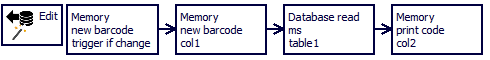

This example reads a barcode, gets the print data from a database and prints the result.

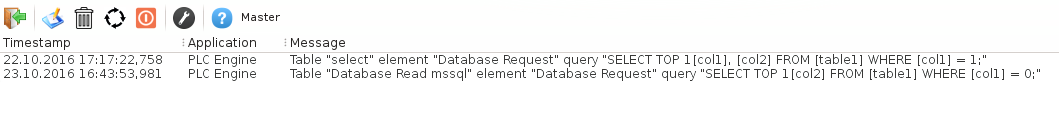

Diagnostics boost the startup in plants. Use Your smartphone or tablet and all of the status displays.

The diagnostics logger handles longer running information collecting.

PLC Engine Collect is made for heterogeneous networks with different controllers and devices from lot of different vendors.

| Supported controller types and devices |

|

| Supported OPC interfaces |

|

| Supported MQTT interface |

|

| Supported databases |

|

| Supported operation systems |

|

| Basis | Siemens | Rockwell | Mitsubishi | IEC60870 | BACnet | De Luxe | Multix | Maximum | ||

| Transport- protocols | TCP/IP | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| OSI/H1 | ✔ | |||||||||

| Application- protocols | Siemens S7 1500/1200 300/400 | ✔ | ✔ | ✔ | ✔ | |||||

| Siemens S5 | ✔ | ✔ | ✔ | |||||||

| ControlLogix CompactLogix SLC PLC5 Micro8xx | ✔ | ✔ | ✔ | ✔ | ||||||

| Mitsubishi | ✔ | ✔ | ✔ | ✔ | ||||||

| BACnet | ✔ | ✔ | ✔ | ✔ | ||||||

| KNX | ✔ | ✔ | ✔ | ✔ | ||||||

| IEC 60870-5 | ✔ | ✔ | ✔ | ✔ | ||||||

| Modbus | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| MQTT | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| OPC UA | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Send / Receive | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Windows OPC DA classic | ✔ | ✔ |

| PLC Engine Collect Multix 100 Client Connections, 50 000 Items, 200 Logic Tables | |

| Database Large, 500 Logic Tables PLC Engine Collect Multix Database Large for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 100 PLC Client Connections • 50 000 Items • 500 Logic Tables • 20 Database Connections • 2 000 Elements per Logic Table • 100 OPC UA Client Connections • 100 OPC Pipe Client Connections • 200 OPC UA Server Connections • 100 OPC Pipe Server Connections • 100 MQTT Connections • 100 KNX Client Connections • 100 PLC Server Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S5 Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Modbus TCP/RTU Server Connections • Raw Data Connections • E-Mail Send Connections • BacNet Connections • KNX Connections • IEC60870-5-104 / DNP3 Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • OPC UA Internal Variable Access • OPC UA Remote Procedure Calls • OPC UA Events • Item Redirect Connection | 104-0031-06 V2 |

| Database PLC Engine Collect Multix Database for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 100 PLC Client Connections • 50 000 Items • 200 Logic Tables • 20 Database Connections • 2 000 Elements per Logic Table • 100 OPC UA Client Connections • 100 OPC Pipe Client Connections • 200 OPC UA Server Connections • 100 OPC Pipe Server Connections • 100 MQTT Connections • 100 KNX Client Connections • 100 PLC Server Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S5 Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Modbus TCP/RTU Server Connections • Raw Data Connections • E-Mail Send Connections • BacNet Connections • KNX Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • OPC UA Events • Item Redirect Connection | 104-0031-05 V2 |

| Multix M PLC Engine Collect Multix Multix M for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 100 PLC Client Connections • 50 000 Items • 200 Logic Tables • 2 000 Elements per Logic Table • 100 OPC UA Client Connections • 100 OPC Pipe Client Connections • 200 OPC UA Server Connections • 100 OPC Pipe Server Connections • 100 MQTT Connections • 100 KNX Client Connections • 100 PLC Server Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S5 Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Modbus TCP/RTU Server Connections • Raw Data Connections • E-Mail Send Connections • BacNet Connections • KNX Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • OPC UA Internal Variable Access • OPC UA Remote Procedure Calls • OPC UA Events • Item Redirect Connection | 104-0031-07 V2 |

| Multix Normal PLC Engine Collect Multix for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 100 PLC Client Connections • 50 000 Items • 200 Logic Tables • 2 000 Elements per Logic Table • 100 OPC UA Client Connections • 100 OPC Pipe Client Connections • 200 OPC UA Server Connections • 100 OPC Pipe Server Connections • 100 MQTT Connections • 100 KNX Client Connections • 100 PLC Server Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S5 Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Modbus TCP/RTU Server Connections • Raw Data Connections • E-Mail Send Connections • BacNet Connections • KNX Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • OPC UA Events • Item Redirect Connection | 104-0031-04 V2 |

| PLC Engine Collect Standard 50 Client Connections, 10 000 Items, 100 Logic Tables | |

| Siemens S7 1500 PLC Engine Collect Standard Siemens S7 1500 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections • 10 000 Items • 100 Logic Tables • 1 000 Elements per Logic Table • 50 OPC UA Client Connections • 50 OPC Pipe Client Connections • 100 OPC UA Server Connections • 100 OPC Pipe Server Connections • 50 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • Item Redirect Connection | 104-0011-02 V2 |

| Basis PLC Engine Collect Standard Basis for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections • 10 000 Items • 100 Logic Tables • 1 000 Elements per Logic Table • 50 OPC UA Client Connections • 50 OPC Pipe Client Connections • 100 OPC UA Server Connections • 100 OPC Pipe Server Connections • 50 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Allows the use of Addon licenses • Dynamic Connection and Variable Creation • Item Redirect Connection | 104-0001-01 V2 |

| PLC Engine Collect Small 5 Client Connections, 3 000 Items, 25 Logic Tables | |

| Interconnection PLC Engine Collect Small Interconnection for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 5 PLC Client Connections • 3 000 Items • 25 Logic Tables • 500 Elements per Logic Table • 5 OPC UA Client Connections • 5 OPC Pipe Client Connections • 20 OPC UA Server Connections • 20 OPC Pipe Server Connections • 5 MQTT Connections Licensed features: • TCP/IP Connections • OSI/H1 Connections • Serial Connections • Siemens S5 Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0431-01 V2 |

| PLC Engine Collect Small Database 5 Client Connections, 3 000 Items, 25 Logic Tables | |

| Siemens S7 PLC Engine Collect Small Database Siemens S7 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 5 PLC Client Connections • 3 000 Items • 25 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 5 OPC UA Client Connections • 5 OPC Pipe Client Connections • 20 OPC UA Server Connections • 20 OPC Pipe Server Connections • 5 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0311-01 V2 |

| Rockwell PLC Engine Collect Small Database Rockwell for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 5 PLC Client Connections • 3 000 Items • 25 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 5 OPC UA Client Connections • 5 OPC Pipe Client Connections • 20 OPC UA Server Connections • 20 OPC Pipe Server Connections • 5 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Rockwell CompactLogic/ControlLogix Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0321-01 V2 |

| Basis, 20 Client Connections PLC Engine Collect Small Database Basis for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 20 PLC Client Connections • 3 000 Items • 25 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 5 OPC UA Client Connections • 5 OPC Pipe Client Connections • 20 OPC UA Server Connections • 20 OPC Pipe Server Connections • 5 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0301-01 V2 |

| PLC Engine Collect Minimum 2 Client Connections, 1 000 Items, 10 Logic Tables | |

| Multix PLC Engine Collect Minimum Multix for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 100 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Rockwell CompactLogic/ControlLogix Connections • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • BacNet Connections • KNX Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0131-02 V2 |

| Siemens S7 1500 PLC Engine Collect Minimum Siemens S7 1500 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 100 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0111-02 V2 |

| Rockwell PLC Engine Collect Minimum Rockwell for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 100 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Rockwell CompactLogic/ControlLogix Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0121-01 V2 |

| Basis PLC Engine Collect Minimum Basis for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 100 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0101-01 V2 |

| PLC Engine Collect Minimum Database 2 Client Connections, 1 000 Items, 10 Logic Tables | |

| Siemens S7 PLC Engine Collect Minimum Database Siemens S7 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0211-01 V2 |

| Rockwell PLC Engine Collect Minimum Database Rockwell for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Rockwell CompactLogic/ControlLogix Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0221-01 V2 |

| Basis PLC Engine Collect Minimum Database Basis for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 PLC Client Connections • 1 000 Items • 10 Logic Tables • 20 Database Connections • 1 000 Elements per Logic Table • 2 OPC UA Client Connections • 2 OPC Pipe Client Connections • 10 OPC UA Server Connections • 10 OPC Pipe Server Connections • 2 MQTT Connections Licensed features: • TCP/IP Connections • Serial Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0201-01 V2 |

| PLC Engine Collect Nano 1 Client Connection, 10 Items, 5 Logic Tables | |

| Siemens S7 PLC Engine Collect Nano Siemens S7 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 1 PLC Client Connection • 10 Items • 5 Logic Tables • 100 Elements per Logic Table • 1 OPC UA Client Connection • 1 OPC Pipe Client Connection • 5 OPC UA Server Connections • 5 OPC Pipe Server Connections • 1 MQTT Connection Licensed features: • TCP/IP Connections • Serial Connections • Siemens S7-200/300/400 Connections • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0511-01 V2 |

| Basis PLC Engine Collect Nano Basis for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 1 PLC Client Connection • 10 Items • 5 Logic Tables • 100 Elements per Logic Table • 1 OPC UA Client Connection • 1 OPC Pipe Client Connection • 5 OPC UA Server Connections • 5 OPC Pipe Server Connections • 1 MQTT Connection Licensed features: • TCP/IP Connections • Serial Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • E-Mail Send Connections • OpcPipe Server Connections • OPC UA Server Connections • OpcPipe Client Connections • OPC UA Client Connections • MQTT Connections • PLC Data Server Functionality • PLC Access Functionality • Minimal Logic Tables Functionality • Full Logic Tables Functionality • Dynamic Connection and Variable Creation • Item Redirect Connection • Doesn't allow the use of Addon licenses | 104-0501-01 V2 |

| Extension | |

| OPC DA Client Functions Extension OPC DA Client Functions for Windows 7 and newer on PC • 200 OPC DA Client Connections Licensed features: • OPC DA Client Connections | 101-0000-03 V2 |

| OPC DA Server Functions Extension OPC DA Server Functions for Windows 7 and newer on PC • 200 OPC DA Server Connections Licensed features: • OPC DA Server Functionality | 101-0000-01 V2 |

| 2 500 Connections 4 000 000 Items Extension 2 500 Connections 4 000 000 Items for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 2 500 PLC Client Connections • 4 000 000 Items • 2 500 OPC UA Client Connections • 2 500 OPC UA Server Connections • 2 500 MQTT Connections • 2 500 IEC104 Client Connections • 2 500 PLC Server Connections | 101-0001-08 V2 |

| Siemens S7 1500 Extension Siemens S7 1500 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections Licensed features: • Siemens S7-1200/1500 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • PLC Access Functionality | 100-0001-08 V2 |

| Siemens S7 200/300/400 Extension Siemens S7 200/300/400 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections Licensed features: • Siemens S7-200/300/400 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • PLC Access Functionality | 100-0001-09 V2 |

| Siemens S5 Extension Siemens S5 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections Licensed features: • Siemens S5 Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • PLC Access Functionality | 101-0011-03 V2 |

| Rockwell Extension Rockwell for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections Licensed features: • Rockwell CompactLogic/ControlLogix Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • PLC Access Functionality | 101-0021-02 V2 |

| Mitsubishi Extension Mitsubishi for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections Licensed features: • Mitsubishi Melsec Q Connections • Modbus TCP/RTU Client Connections • Raw Data Connections • PLC Access Functionality | 101-0051-02 V2 |

| BACnet KNX Extension BACnet KNX for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections • 50 KNX Client Connections Licensed features: • Modbus TCP/RTU Client Connections • Raw Data Connections • BacNet Connections • KNX Connections • PLC Access Functionality | 100-0001-04 V2 |

| OPC DA Client and Server Extension OPC DA Client and Server for Windows 7 and newer on PC • 200 OPC DA Client Connections • 200 OPC DA Server Connections Licensed features: • OPC DA Server Functionality • OPC DA Client Connections | 100-0001-03 V2 |

| Serial Connections Extension Serial Connections for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others Licensed features: • Serial Connections | 100-0001-05 V2 |

| 200 Connections 1 000 000 Items Extension 200 Connections 1 000 000 Items for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 200 PLC Client Connections • 1 000 000 Items • 200 OPC UA Client Connections • 200 OPC UA Server Connections • 200 MQTT Connections • 200 IEC104 Client Connections • 200 PLC Server Connections | 101-0001-02 V2 |

| 100 000 Items Extension 100 000 Items for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 100 000 Items | 101-0001-06 V2 |

| 1 000 Connections Extension 1 000 Connections for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 1 000 PLC Client Connections • 1 000 OPC UA Client Connections • 1 000 OPC UA Server Connections • 1 000 IEC104 Client Connections • 1 000 PLC Server Connections | 100-0001-02 V2 |

| Redundancy Extension Redundancy for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others Licensed features: • Redundancy Connections | 100-0001-01 V2 |

| IEC60870-5-104 Extension IEC60870-5-104 for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 50 PLC Client Connections • 100 IEC104 Client Connections Licensed features: • Modbus TCP/RTU Client Connections • Raw Data Connections • IEC60870-5-104 / DNP3 Connections • PLC Access Functionality | 100-0001-06 V2 |

| PLC Password Extension PLC Password for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others Licensed features: • PLC Password | 100-0001-11 V2 |

| Extension PLC Engine Collect | |

| 10 000 Elements per Logic Table Extension PLC Engine Collect 10 000 Elements per Logic Table for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 10 000 Elements per Logic Table | 104-0001-10 V2 |

| 10 000 Logic Tables Extension PLC Engine Collect 10 000 Logic Tables for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 10 000 Logic Tables • 3 000 Elements per Logic Table | 104-0001-05 V2 |

| Database Access Extension PLC Engine Collect Database Access for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others • 20 Database Connections Licensed features: • MySql Connections • MsSql Connections • ODBC Connections • PostgreSQL Connections | 104-0001-02 V2 |

| Extended OPC Services for Machine Models Extension PLC Engine Collect Extended OPC Services for Machine Models for Windows 7 and newer on PC, Linux for PC, Raspberry, Odroid and others Licensed features: • OPC UA Internal Variable Access • OPC UA Remote Procedure Calls • OPC UA Events | 104-0001-08 V2 |

| Tools | |

| OPC UA Modeler OPC UA Modeler | 107-0001-01 V2 |

Software protection with dongle